For professionals in construction and woodworking, precision and power are non-negotiable. Advanced worm drive and rail saws have become essential tools, offering unmatched performance for demanding applications. These tools are engineered to deliver accuracy, durability, and efficiency, making them indispensable for experts who require flawless results.

Whether it’s cutting through dense materials or achieving perfectly straight lines, these saws cater to a wide range of professional needs. Their innovative designs and robust features ensure they stand up to the toughest tasks while enhancing productivity. For those seeking tools that combine reliability with advanced technology, worm drive and rail saws are game-changers.

Precision Cutting with Worm Drive Saws

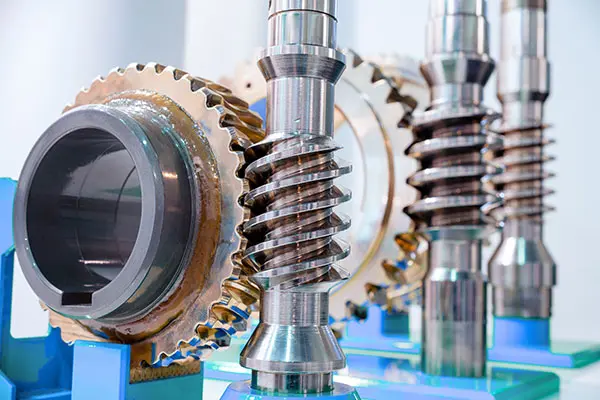

Worm drive saws are renowned for their precise cutting capabilities in professional applications. Their gear-driven motor placement increases torque, making them ideal for cutting dense materials like hardwood, engineered wood, and metal. This design ensures a smoother operation and reduces the risk of blade deflection.

The longer blade orientation in worm drive saws enhances cutting accuracy. By aligning the blade parallel to the handle, users can maintain better control during extended cutting tasks. These saws also excel in bevel cuts, enabling sharp and clean angles for complex projects like custom cabinetry or framing.

High torque output allows worm drive saws to maintain consistent cutting speed under heavy workloads. Their durability, paired with precision gearing, makes them a preferred tool for industries requiring reliability and high performance, including construction and woodworking. Advanced models often feature enhancements like dust collection systems and ergonomic grips, prioritizing user comfort and safety.

Features That Make Rail Saws Ideal for Professionals

Exceptional Cutting Precision

Rail saws deliver accurate, straight cuts, ensuring precision on materials like tile, granite, and engineered stone. Guided rails stabilize the saw, minimizing deviations for clean and consistent results even in extensive applications. This feature benefits professionals working on intricate designs or installations.

Versatility in Material Handling

High-performance rail saws handle various materials, including ceramic, porcelain, and glass. Adjustable depth settings and blade alignment accommodate diverse thicknesses and textures, enhancing adaptability for differing project requirements.

Enhanced Durability and Build Quality

Engineered with robust materials, professional-grade rail saws withstand heavy-duty use. Durable components, such as corrosion-resistant rails and reinforced frames, extend operational lifespan, catering to long-term industrial use.

Advanced Water Management Systems

Integrated water cooling systems reduce blade wear and minimize dust, maintaining operational efficiency. Consistent water flow cools cutting zones effectively, ensuring smoother operation during demanding work conditions.

Ergonomic Design for User Comfort

Ergonomic handles, adjustable components, and lightweight designs minimize strain during extended use. These ergonomic considerations enhance control and reduce operator fatigue, boosting overall productivity.

Professionals accessing product specifications or purchasing reliable rail saws can view tools from BB Industries through their website, offering an array of functional options tailored for high-precision tasks.

Comparing Cutting Solutions for Complex Tasks

Advanced worm drive and rail saws excel in meeting the demands of intricate cutting tasks with their precise performance and robust functionality. Worm drive saws handle challenging materials like engineered wood, hardwood, and dense metals through their high torque output and long blade orientation, ensuring controlled, accurate cuts in complex projects such as bevels. These saws maintain consistency during heavy workloads, making them indispensable in professional applications requiring sustained performance.

Rail saws, on the other hand, are engineered for straight, accurate cuts on diverse materials like granite, tile, and engineered stone. Their guided rail systems prevent alignment issues, accommodating delicate materials like ceramic and glass while reducing error rates. Adjustable depth settings enhance versatility, enabling professionals to tackle multiple layers or variations within a single project. Durability features, including water management systems, ensure reduced blade wear and minimal debris during extended usage.

Professionals seeking enhanced cutting efficiency for specialized tasks can consider the varied options offered by BB Industries. Exploring solutions through their website provides access to high-precision tools tailored for demanding applications.

Benefits of Using Advanced Tools for Construction Projects

Advanced tools streamline construction processes and enhance project outcomes. Worm drive and rail saws help professionals achieve higher levels of precision and efficiency. Their designs cater to challenging environments, reducing errors and increasing overall productivity.

- Enhanced Accuracy for Complex Tasks

Advanced saws incorporate innovative mechanisms like guided rails and torque-driven motors, ensuring precise cuts. These tools minimize material wastage and guarantee consistent results, particularly when handling intricate projects. - Time-Saving Features

Worm drive saws and rail saws accelerate operations with powerful cutting capabilities. High-torque performance and adjustable settings allow users to complete tasks faster, especially when working with dense or delicate materials. - Extended Tool Durability

Premium materials and advanced technologies extend the lifespan of these saws. Features like advanced water management systems and dust control reduce wear-and-tear on components during heavy-duty projects. - Improved Safety and Ergonomics

Ergonomic grips and balanced designs enhance user safety and comfort while operating saws. Additional features, such as dust collection systems, ensure cleaner workspaces, minimizing risks posed by airborne particles.

Professionals can browse the BB Industries Website for a wide selection of these cutting-edge tools, tailored to meet rigorous construction demands.

How to Select the Right Saw for Your Applications

Identifying the best saw for professional tasks depends on understanding the application requirements and tool capabilities. Matching material types, accuracy needs, and project complexity with the right saw optimizes performance.

- Consider Material Types

Worm drive saws handle dense materials like hardwood, engineered wood, and metal effectively, using their torque-driven systems to maintain cutting precision. Rail saws deliver clean, straight cuts on ceramics, granite, and glass, aided by guided rails and water management systems. - Evaluate Cutting Requirements

For high-torque and bevel cutting applications, worm drive saws provide consistent performance, even for intricate tasks. Professionals working on straight-cut materials or requiring adjustable depth settings benefit from the precision-guided functionality of rail saws. - Assess Durability and Usage Frequency

Advanced worm drive saws feature durable motors and ergonomic designs for heavy-duty tasks. Rail saws, built for daily intensive use, include robust frames and advanced components like dust reduction technology to enhance longevity. - Focus on Ergonomics and Safety Features

Both tool types prioritize user convenience. Worm drive saws include ergonomic grips and balanced designs for extended tasks, while rail saws ensure stability and reduce operator fatigue through guided rail systems and ergonomic layouts. - Leverage Supplier Expertise

For reliable advanced saws tailored to diverse applications, exploring the BB Industries website provides access to professionally curated options, ensuring tools meet rigorous construction needs for precision and efficiency.

Maintenance Tips for High-Performance Cutting Tools

Proper maintenance ensures worm drive and rail saws deliver consistent performance and extend their lifespan. Regularly inspecting blades for wear and replacing them as needed preserves cutting precision. Cleaning the saw after each use prevents dust buildup and protects internal components.

Lubricating moving parts and checking alignment are essential for smooth operation and long-term durability. For rail saws, keeping the guide rails clean and free of debris ensures accurate cuts and prevents misalignment. Always store tools in a dry, secure location to avoid exposure to moisture and potential damage.

By investing time in routine care, professionals can maximize the efficiency and reliability of their cutting tools, ensuring they remain indispensable assets for demanding applications.